OC Transpo is warning the Confederation Line will be partially shut down in October as work continues to enhance the reliability of the nearly five-year-old light-rail transit system.

No details about the partial shutdown of the O-Train Line 1 are included in a report for the Transit Commission and Light Rail Sub-Committee outlining the steps being taken to address issues following the first LRT derailment in 2021. The city tells CTV News Ottawa that “future details on next steps” will be shared at a May 31 meeting.

The report provides an update on the status of mitigation measures related to the cartridge bearing assembly on the Alstom vehicles and the progress to identify the root cause and development of a sustainable solution. It says Rideau Transit Group has responded to several of the recommendations to improve reliability, but there remains a lack of consensus on the root causes of the axle issues.

“Automated gauge face lubrication, top-of-rail friction modifiers, restraining rail resetting, railhead reprofiling, nut-pinning and ballast strengthening are all improvements that will enhance reliability of the system,” says the report for the Friday, May 31 committee meeting.

“Further work will occur during a partial shutdown in October 2024 including a grinding program to re-establish the rail head profile and track ballast strengthening.”

Last October, Alstom told councillors that the issues with the axle hub assembly are due to the higher than expected lateral loads on the vehicle’s axles during operation. Three issues with the cartridge bearing assembly have led to the full or partial shutdown of the LRT line, including the full shutdown of the system last July after the discovery of an issue with one wheel hub.

Alstom submitted several recommendations to address the issue, including deploying top-of-rail friction modifier, which is a lubrication that can reduce lateral loads along the line, and moving the restraining rail.

The report says Rideau Transit Group is working with its own engineering firm to review the Alstom report and will “will produce a consolidated document that captures the findings of all reports completed to date.”

Rideau Transit Maintenance and Alstom have committed to several short, medium and long-term actions to resolve the issue and increase rail service reliability.

“Various containment measures have been implemented on the Confederation Line to ensure the continuation of safe LRT service,” the report says.

“Simultaneously, the City, RTG, and their external safety and engineering consultants continue to make progress on the development of additional mitigation measures that will provide a stable and resilient LRT service.”

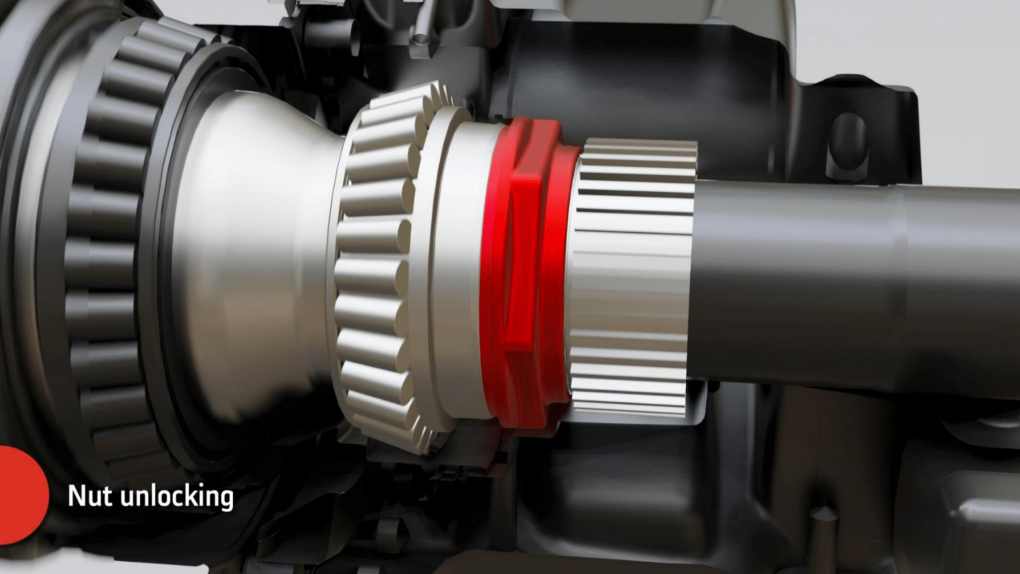

While Alstom has committed to redesigning the axle of the vehicle hubs in the long term, the short-term solution to place a pin in the restraining nut on the axle hubs to prevent it from unscrewing.

The report says half of the vehicles have received the pinned hub replacement, as OC Transpo and Rideau Transit Maintenance install the new hubs on all vehicles. Staff say the new pin hub will extend the inspection window from 60,000 kilometres to 400,000 kilometres or five years.

Alstom released pictures of the axle of an Ottawa LRT vehicle and the nut unlocking. (City of Ottawa/report)

Alstom released pictures of the axle of an Ottawa LRT vehicle and the nut unlocking. (City of Ottawa/report)

Here is a look at other short, medium and long-term solutions:

Speed restrictions (short): Temporary speed restrictions remain in place along sections of the track with a curve under a 250-metre radius.

Restraining Rail Adjustment (short): Rideau Transit Group maintains the restraining rail in a “no-contact” position in adherence to the Alstom safety note requirements.

Top of Rail Lubrication (medium): Rideau Transit Group has installed wayside equipment along the LRT line for deployment of Top-of-Rail friction modifiers. “The precise deployment of friction modifier will reduce the friction between the wheels and railhead and will diminish noise and vibration and the lateral force applied to the LRV cartridge bearing assemblies.{ Twelve of the 21 lubrication devices have been commissioned so far, with the remaining devices to be installed by the end of May.

Bearing Condition Detectors (medium): “The (National Research Council) has successfully designed, fabricated, and commissioned a wheel, bearing and brake testing rig to accept the axle configuration from the Alstom Citadis Spirit LRV.” The report says testing continues.

Re-design of the Cartridge Bearing Assembly (long-term): “The cartridge bearing assembly redesign will focus on strengthening the structure of the assembly to better withstand the lateral forces experienced on the Confederation Line and deliver a product that meets reliability, availability, maintainability, and safety requirements,” the report says. “Alstom has indicated that a Sustainable Solution can be achieved without a redesign and is not currently working on this initiative.”

Staff note the mitigations does not resolve the “outstanding lack of consensus on root causes” of the cartridge bearing assembly failures.

“It is imperative that RTG works with its track and vehicle teams to reach agreement on the corrective action plan that will ensure the sustainability of the railway.”